By: Jag Dhatt

Gothenburg, Sweden: There is a Swedish word called “lagom” which describes something that is in the perfect condition or amount. It’s a general word that can be applied to many things, but for the city of Gothenburg, it seems especially fitting. Situated on the western coast of Southern Sweden, Gothenburg is home to Volvo Trucks (and the Volvo Group) and the city in which things can be described as lagom; it’s not too big and not too small; it has traditional and modern buildings; and it has the mind-set of developing things that keep traditional values while looking towards the future.

In recent years, there has been a push towards electrification; it’s also safe to say that COVID was partly responsible for speeding up this push. Seven years ago, nobody thought the electrification of heavy trucks was possible and today, companies like Volvo are doing what is necessary for the benefit of the global environment.

Volvo Electrifies:

Assembled in 12 countries, Volvo Trucks operates in over 190 countries, with a focus on trucks, construction, boats and buses. While the internal combustion engine is still the power plant in most Volvo trucks, the manufacturer has emerged as a leader in heavy truck electrification. And it has to do with their fundamental values and beliefs.

At heart, a core Scandinavian belief is to be in tune with and appreciate nature and the environment. “Yes, we need to adjust our technology to adjust to climate change, but we also need to do what’s necessary to reduce climate change and alternate fuel sources are a start,” says Roger Alm, President of Volvo Trucks. “We are on the way to electrification and zero emissions, with over 6 electric models in production.”

Volvo Trucks has become the leader in market share in the global market. While the public doesn’t see much of that happening in North America, it’s clearly evident in Europe. 45% of all goods in the European Union travel less than 300 km. With shorter drive routes, Volvo electric trucks are being used more and more, with some companies even making a complete shift.

Hagen’s Transport, based in Norway, is one such example. After adding some new Volvo FM models to their fleet, the company has said it will not be going back to diesel power. “Our route around Oslo is about 200 km and the Volvo FM Electric has a range of 300 km,” says Kai Hagen. “It is a perfect truck for our company, and we can even use it in two shifts. We are doing our part for the environment.”

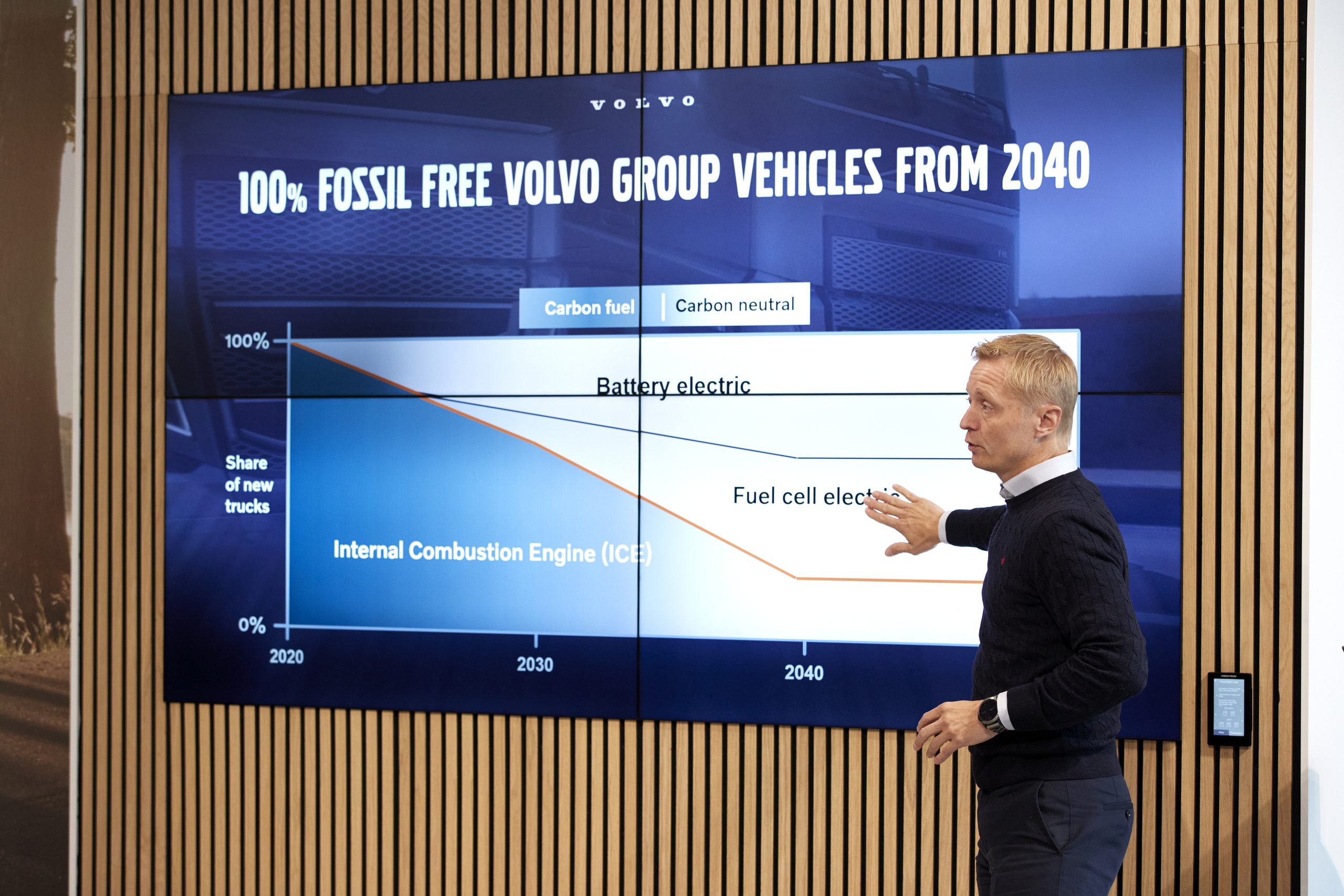

Taking care of the environment is a global effort and as Roger Alm says, “It’s our responsibility to care for the future generations because we are the generation that can change the future for the better. Thus, by 2040, all Volvo products will be 100% fossil free and 100% net zero emission by 2050.”

Volvo Electric and Beyond:

Electric trucks are here, but there’s more to the future than just electric, and Volvo recognizes this reality. For now, the manufacturer states that internal combustion engines are, and will be, around, but there must still be more alternate fuel sources.

“We have battery [power] already and we are now doing research in the development in fuel cell technology,” says Jessica Sandstrom, Head of Product Management at Volvo Trucks. “But again, the technology will depend on the usage.”

“It is safe to say that the majority of regional needs can be fulfilled by using battery electric,” says Johan Larsson, VP Electromobility Business Development at Volvo Trucks. “Long haul can be either battery or internal combustion engine, LNG or diesel.”

But the ideal layout would be an internal combustion engine with hydrogen integration, especially with lower emissions. “A fuel cell is more expensive to produce but has 100% zero emissions and is highly energy efficient,” says Johan Lunden, Senior VP Project and Product Strategy for Volvo Trucks. And in order to achieve the ideal engine, Volvo says it’s necessary to work with competitors to build new technology, something nobody thought would be possible. But then, nobody thought electrification of heavy trucks was possible. Volvo is now doing both.

All of this forward-thinking technology is no small feat, yet small steps will make the path easier. Volvo Trucks currently modifies Samsung batteries to work in their trucks. In 2024, the truck manufacturer will build its first battery plant in, you guessed it, Sweden. Not only is it important to keep manufacturing close to home, Sweden also has an abundant source of green energy and thus, will lower the footprint because battery production is a high energy process.

Volvo’s Circular Economy Transformation:

History has shown that most manufactured goods follow a similar process: take resources from the planet, manufacture products, use products, discard products and repeat. This linear flow of production has been used since the dawn of industrialization, and now, more than ever, it needs to change.

In addition to developing alternate fuel sources, the Volvo Group believes that the final goal of a circular economy can only be achieved when our societies thrive without depleting the planet’s natural resources. Circularity must become a reality as the planet can no longer deal with resource depletion, high emissions, and increasing waste.

“Refurbishing, remanufacturing and recycling of materials are cornerstones in the circular economy – and have been integral parts of Volvo Group’s business for a long time,” says Lars Martensson, Environmental and Innovation Director at Volvo Trucks. “Besides being the right thing to do, circularity is about improved resource-efficiency that comes with significant cost saving opportunities.”

And it’s not all just talk. About one-third of a new Volvo Truck’s total weight is made from recycled material and about one half of the wrought iron is acquired from recycled metal and 97% of the cast iron is made from recycled iron.

Volvo Trucks has even begun to use what some would call waste as a resource to be used inside the trucks. From wood and plastics to cloth, much of this can be recycled and used in the cab of the truck.

So, what about after the truck has seen its time of use and needs to move on? According to one study, there is a theoretical possibility of recycling 95% of the VNR Electric. The reality of it will depend on location, recycling practices and partners, and legislations of various countries. The important note to take away is that the vision to achieve this goal is there.

Where Do We Go From Here:

When it comes to the electrification of heavy trucks, we’ve come a long way in just a short amount of time. Many thought diesel power would be around years to come, yet the reality is that our planet’s resources cannot keep up with global demand. Volvo Trucks is leading the charge for transport efficiency by investing time, energy, money and resources in developing new technology while not sacrificing safety. But it will take more than that.

Kristina Nilsson, Head of Charging Infrastructure Solutions at Volvo Trucks, says that while it’s important to develop new technology, having strategic partnerships is crucial as a society. “We must have partnerships to build infrastructure to sustain electric and other alternate fuel sources. And that’s why we are working with Pilot Company to build such infrastructure.”

Proof of Volvo’s goals of zero emissions and being fossil free are already on the streets of Europe. The FM Electric is one of many electric trucks at the Volvo Trucks Demonstration Center in Gothenburg. Then there’s a prototype fuel-cell-electric Volvo FH being tested and demonstrated at the Hallered Proving Grounds. Finally, there’s a FH running on liquefied natural gas (LNG); in fact, some LNG Volvo trucks will be coming to Canada on a pilot program.

The world is changing quickly when it comes to alternate fuel sources and zero emissions. And Volvo Trucks is a global leader in the change towards a greener planet.