OEMs, fleet operators and owner operators often consider the balance between performance and cost in making decisions regarding braking systems; and that consideration also often focuses on the debate: Air Disc Brakes (ADBs) vs. drum brakes. Let’s look at some information that is important to that decision making.

Drum brakes are the traditional choice of some fleets and operators because of familiarity with that brake system and a perceived cost advantage. ADB system technology, however, has driven greater adoption of ADBs industry-wide because of important advantages throughout the brake lifecycle.

Let’s start with stopping.

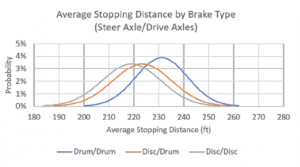

A North American study published by the U.S. Federal Motor Carrier Safety Administration (FMCSA)1 analyzing the variability of heavy truck braking systems found that the average stopping distance for disc/disc configuration of brakes (meaning, disc brakes on both the steer axle and drive axles) was shorter than either drum/drum or disc/drum brake configurations. Therefore, performance as measured by stopping distance favors ADBs. There are other advantages as well.

Drum brake systems are a fully closed design. As drum brake systems heat up, particularly during heavy braking, they are prone to brake fade – a reduction in performance due to expansion of the drum away from the brake shoe friction. In contrast, ADB technology, which uses a disc that is fitted with a caliper to stop the rotor, virtually eliminates brake fade. Since the rotor is exposed to outside air, it cools quickly, decreasing the tendency to overheat and cause fading.

Drum brake systems are a fully closed design. As drum brake systems heat up, particularly during heavy braking, they are prone to brake fade – a reduction in performance due to expansion of the drum away from the brake shoe friction. In contrast, ADB technology, which uses a disc that is fitted with a caliper to stop the rotor, virtually eliminates brake fade. Since the rotor is exposed to outside air, it cools quickly, decreasing the tendency to overheat and cause fading.

As noted in FMCSA study, any brake life cycle varies due to many factors including road conditions, the average load of the vehicle, the terrain traveled – flat or hilly, and even the driver’s skill level. But in comparable circumstances and conditions like those presented in the study, ADBs offer two important advantages: shorter stopping distance and more efficient heat transfer in the act of braking.

That brings us back to the question – how does value relate to performance? In comparing the stopping performance of drum brake systems to ADB technology, the performance advantage goes to ADBs.

An even greater advantage is available with ZF ADB technology – WABCO MAXXUS™ 2.0. Its single-piston design makes it the lightest truck ADB on the market. It also offers comparable output force to double-piston technology, better heat management – which results in longer brake life, less grab and pull, and greater stopping power and a 10% shorter stopping distance than the U.S. Federal Motor Vehicle Safety Standard (FMVSS) requirement, which is harmonized with the CMVSS.2

Returning to the question; “how do I define value regarding my heavy truck braking system?” Thoughtful consideration, based on performance and comparative data, makes ADB technology the answer.

1 FMCSA-RRT-19-005(b), January 2021

2 hvttforum.org, WP: Brake System Comparison for European and North American Heavy Vehicles, Hart and Bruzsa

You can also find the article in: https://www.wabco-customercentre.com/solutioncentre/s/article/ADB-vs-DB?language=en_US

Want to learn more about MAXXUS 2.0 ADB? – https://www.wabco-auto.com/americas_en/Special-pages/Promotions/MAXXUS